Digital tomosynthesis – a quicker way for 3D X-Ray NDT inspection for; composites, batteries, metal additive and welding.

Adaptix are transforming inspection economics with the next generation of Non-Destructive Testing (NDT) technology.

Adaptix’s method of imaging is Digital Tomosynthesis (DT). DT is already used widely in the medical imaging sector for breast imaging. It helps to better characterize equivocal lesions in planar chest X-rays and can optimize the use of CT resources. Adaptix have developed this technology which has enabled the design of compact, affordable DT systems that allows easier access to low-dose 3D imaging in both medical and industrial settings.

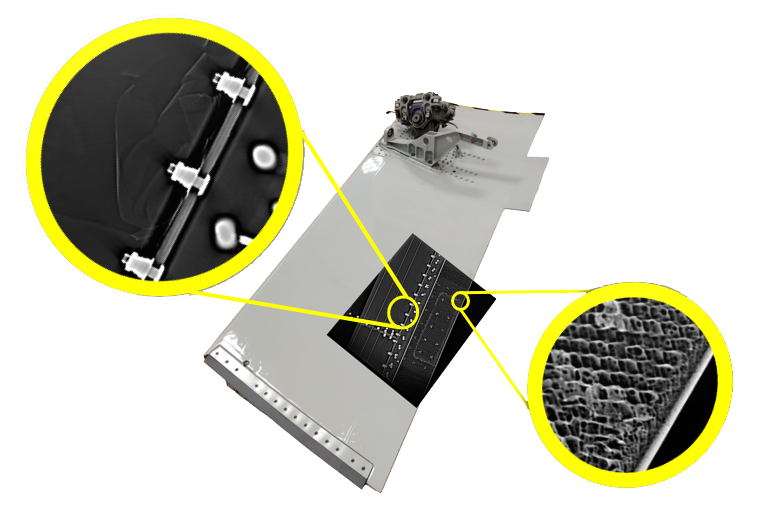

Adaptix NDT3D provide systems and services to industries such as Aerospace, Automotive, Engineering. The unique technology to transforming industrial radiography.

Adaptix NDT3D technology is enabling:

- R&D project crashing for faster evolution of new composite manufacturing methods and materials

- 3D X-ray for fast, routine use

- Deployable 3D X-ray for maintenance and manufacturing

- Unique dry-preform inspection of composites resulting in:

-

Reduced costs due to finding faults/rework ~65% sooner in process

-

Reduced material waste resulting in positive environmental impact

-

Increases operating efficiency and effectiveness

-

Unlocking in-house, benchtop 3D X-ray without lab-infrastructure and costs

“What truly sets the Adaptix 3D X-ray scanner apart is the efficiency and speed…the results have been nothing short of exceptional…optimises our workflow and has revolutionised our counterfeit detection procedures.” Azego TS Ltd, Head of Technical Services

In-house 3D testing allowing differentiation and transformation of inspection economics:

- – Compressing inspection cycles

- – Enhancing risk management

- – Reducing inventory holding and

- – Reducing operating costs.